|

Torque Converters, D5 Torque Converters, D5  A higher stall converter is better for getting a car to

move faster from a dead stop. Higher stall will produce more tire burning power for you people that like to judge a car

on how well it burns out, it will also feel and be more powerful coming out of red lights. The stall is how high your engines

RPMs will raise from a dead stop as soon as you mash the peddle so a higher stall converter will come off from a dead stop

at higher RPMs resulting in higher power output to the wheels. On 307s with the 200-4R and 325-4L transmissions there

is 3 converters used, they are labled by stampings on the outer shell of the converter stamper all the way around. The three

converters are D7, D6 and D5. The D6 and D7 were used on basic Vin Y 307s and stalls around 1800 -2000rpm's while the D5 is

used in the Cutlass 442 Vin 9 307s as well as Buick GN's and SS's, the D5 stalls at 2400rpm's so the higher stall of the D5

is what makes it desirable. Most people think that the D5 is hard to find because it was only used in special models like

the 442 but thats not true, they can also be found in Cadillacs from the early to mid 80s with the 4100 FI 4.1 liter V8 and

the 200-4R or 325-4L transmission so if you are on a junkyard search for a D5 I suggest looking for a D5 from one of these

Cadillacs because there are a load of these cars in the junkyard. If you have your trans or engine out it is well

worth it to find one of these converters because its a cheap power improver, I pulled mine myself from a junkyard

and paid 13 bucks.

To check the converter all you do is

well first make sure the trans that the converter is coming from is not killed by checking the fluid for metal flakes, make

sure theres no water in the trans and the lower the miles of the donor car the better. After you get the converter in your

hands stick two fingers into the neck of the converter (takes two hands one finger from both) the inside assembly of the converter

should be able to turn one way but not the other, it will turn the other way if enough force is applyed (and thats normal)

but your naked fingers shouldnt be able to turn it the other way, thats why you should use your fingers and not a tool of

some sort, when it turns it will make a scraping sound thats normal. Look at the neck of the converter for excessive wear,

the bushing rides on the outer side of the converter neck and does leave scoring but it should be smooth and not deep. look

under the front seal of the donor trans for signs of front seal leak, if there is a sign of a leak the converters neck is

most likely damaged as well. I have learned that sometimes GM stampes the D5 sometimes 5D and sometimes just 5, the stamping

is sometimes also very faint maybe even non existing so take that as you may.

Flush it yourself for cheap, Face the

converter neck down in a bucket over night so that it can drain, the next day fill the converter up with clean fluid

roll it around to get every corner then dump it again over night, do that till you are sure all the old fluid is all out,

IF you see metal shreads coming out with the old fluid (looks like sparkles in the fluid) do not put the converter into

your car till you get it pro cleaned from a tranny shop. Cool eh!

|

|

|

|

Modifing the 325-4L in the Riviera, Toronado, & Eldorado.

Well I'm going to provide the info on how to set it up for nice positive quick,

but smooth shifts, then if you ever want to go firmer it would only be a washer or spring away! I like mine to bang through

its gears rock hard but I understand other people might not like that so here we go on how to make nice positive quick but

smooth shifts.>>>>>>>>>>>>

1. Block the line bias vallve closed with a roll pin. This will keep the line

bias valve from bleeding off modulated TV pressure that is lifting the boost valve. This will keep the main line pressure

up high during part and full throttle. By removing the line bios spring and replacing it with a roll pin (or what not) to

hold the valve closed that will do the trick. Look at the attachment Im sending to see were this valve is located on the valve

body.

2. Block the 1-2 accumulater travel partly. The accumulaters job is to soak up the instant pressure going to

the clutch pack, this makes the shifts drag on long and often slip between gears. By blocking the travel this will keep the

accumulater from soaking up the pressure going to the clutches and bands, this will provide a crisp fast shift. Doing this

will actually shortin the time it takes to shift between gears. B&M kits for the 200-4R uses washers under the piston

to limit its travel. For the 1-2 accumulater you will want to put at least a 1/2" spacer/washer (or stack of washers) on the

side of the accumulaters piston that is opposite of the spring. so that the accumulater piston will not be able to reach its

full extension, there for limiting the travel of the accumulater piston. (if you ever want a harder 1-2 shift just block the

piston from moving all together. thats what I do).

For the 3-4th accumulater, heres the crazy part! Notice the 3-4 accumulater

is upside down compared to the 1-2 accumulater, well GM did this to soften the 3-4 shift even more. BUT on the GN and 442

models as well as the Riviera T types GM put the 3-4 accumulater in the same way as the 1-2 for a more progressive shift.

So basicly you want to "flip over" the whole 3-4 accumulater spring and piston to match the 1-2 accumulater spring and piston.

Sounds crazy but trust me! Now you should also limit the travel of the 3-4 accumulater just like you did the 1-2 accumulater

for a more progressive shift. (if you ever want a harder 3-4th shift just block the piston from moving all together. thats

what I do).

3. Pressure regulater valve spring, shim the one already in there just alittle with a washer about 1mm

to 1.5mm thick, the washer must have a big enough center whole to allow the pressure regulaters rod to slide though it (you'll

see what I mean when you remove it) and a small enough outer diameter to alow the washer to go fully into the cavity with

the spring. Put the washer on the bottom side of the spring NOT the top.

Or you can purchase the pressure regulater spring

for the T Type Riviera, that trans has the code BJ on it. This will send more main line pressure through out the whole trans,

this will make for more holding power and will allow the trans valve body to "think" faster! You can buy the spring right

here on this page >>> http://www.acerecon.com/catalog/aut...series.asp?t=18 While your at it you might want to get all the BJ's pressure regulaters parts>>>

Spring - Pressure Regulator ( 1984 BJ ) 3761 1 1984 1233763

Valve -

MTV Boost ( 84-85 BJ ) 3773 1 1984-85 1233775

Valve Sleeve - MTV Boost ( 84-85 BJ ) 3778 1 1984-85 1233778

Valve

Sleeve - Pressure Regulator ( BE BJ AK AG OK ) 3782 1 1979-81 1233783

Or to make it simple and acheive about the

same results just shim your existing spring about 1 mm to 1.5 mm's or so

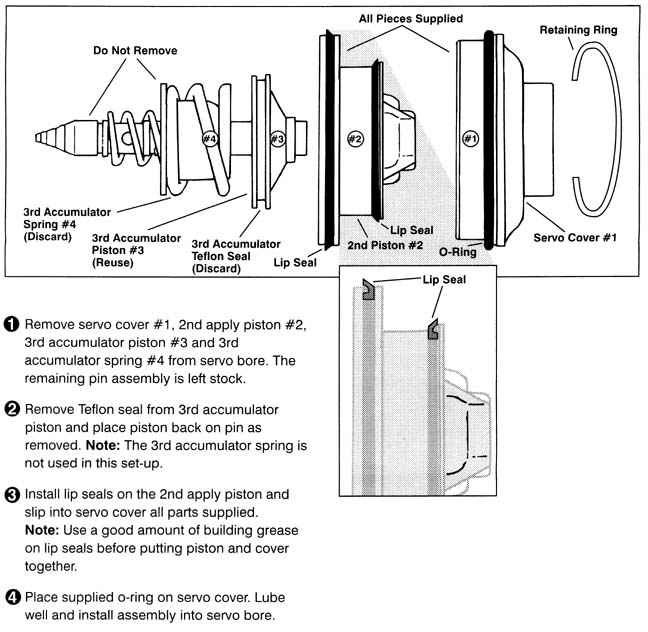

4.Servo, modify the one you have now

by checking out the picture below with the servo. This will provide a solid shift going into 2nd gear and will get rid of

the 2-3 accumulater thats built into the servos design. Not doing this single mod will cause all the others to have very little

effect so please dont skip this one. Actually I think this one is one of the more important ones. (For rock hard shifts use

a super servo or a 200-C's servo from the 200-C trans in the late 70 early 80's)

I assume you know how to tune the governor to the shift points you like, but

if not let me know ans I can provide that info as well!

|

|

|

|

|

Enter content here

|

|

|

|

|