|

Setting the Air Valve tension

The AV is

the flap that covers the secondaries of your carb. It opens up when airflow through the secondaries demands it. Decreasing

tension on it has 2 main benefits. It allows the air valve to open faster, giving you full power sooner by allowing the

secondaries to open fully at lower a lower RPMs on your launch. It also allows the air valve to open more easily with airflow,

giving you the possibility to make more total power. It is held shut by 2 things.

First by the choke pull-off diaphragm (which is a vacume diaphragm on the front pass. side

of the carb.) When the engine is running , the choke pull-off keeps the air valve closed by pulling the linkage via the rod

that connects from the chock pull off to the air valve. When you go to/near WOT, the choke pull-off pulls out(due to the loss

of manifold vacuum) and allows the air valve to open. The pull-off generally releases slowly, slow enough that even with no

air valve spring tension you shouldn't get a bog. The rate at which it pulls out is not adjustable with the metal can pull

offs our carbs came with. If your car bogs bad going inot WOT then this (choke pull-off) should be the first thing to

check, check to see if its getting vacume and if it does not have a leak.

The air valve is also held shut by spring tension, and that

is adjustable. To adjust it, you will need a small allen key (either 3/32 or 5/32, i forget) and a small flat screwdriver.

(**note: it is possible that instead of an allen key you will need a small torx bit, but they are rare.)

1. Look at the pass. side of the carb (with

the air cleaner off) Observe the linkage (rod) on the

side of the air valve. Through the slot you can see a small flat screw. That's the one you need to adjust.

| The set screw is circled in red |

|

| Just under the set screw facing downward is the hex screw that locks the set screw, (red arrow) |

2. To adjust it you need to loosen the setscrew, which is

on the underside of the lip of the airhorn. The setscrew is where the allen/torx bit comes into play. Loosen it only enough

that you can turn the adjusting screw.

3. Turn the adjusting screw counter-clockwise until the air valve flops open on its own. Now slowly turn it

clockwise until the air valve just shuts. That is 0 tension. If you were setting it to factory specs you would then

proceed to turn it down the specified turns (usually 1/2-1 turn). Instead, tighten the setscrew and go drive.(**note: You

may have to hold the air valve rod to the choke pull-off out of the way while you adjust the tension. You can also remove

the choke pull-off, but that is really excessive. If you exercise some common sense, it isn't hard to figure out how to hold

everything.)

4. With

your car fully warmed up, come to a stop and then nail it. Did it bog? If it didn't, consider yourself done. If it did, be

sure your choke pull-off is working properly. If it is bad, it could cause you problems too. you can increase the air

valve tension until the bog goes away. Go in 1/8 turn increments at a time, and

stop when the bog goes away. Do not increase the tension to over 1 turn down or you will permanently distort the spring.

Contact Me!

|

|

|

|

Secondaries

Not Opening is somewhat common for the 307s. The secondaries are locked shut on a cold engine and the

choke's system is what controls this action. I have found that alot of 307s have the choke adjusted too tight and this

causes the secondaries to not open intill the engine gets really warm, sometimes in cool weather they might not ever

open because the engine will not get warm enough for the choke to release the secondaries. If this happens to you then you

might want to adjust the choke alittle looser but if you cant even stand the lockout messing with you ( like me ) then you

can bypass this all together so that the secondaries will open anytime the peddle is floored, but there is one side effect

to this, if the engine is floored while the engine is still cold it may bog real bad so its best to give the engine alittle

running time before going WOT usaly 10 minutes is good enough. If you want to bypass the chocks control over the secondaries

so that they will always open no matter what then just follow these instructions

1. Follow the secondary throttle shaft (the

one on the bottom base of the carb) to the passiger side of the car and look down at the bottom of the carb were the secondary

shaft comes out the carbs base and you will see this little tang (lever) hanging next to the shafts end with a little pin

going right through the secondary throttle shaft, that locks the secondaries from opening while the engine is still cold.

2.What we are going to do is bend the

pin (that goes through the shaft) out of the way using some needle nose plyers so that it will never catch the tang

(lever) and lock out the secondaries (best if bent toward the passinger side front wheel).

3. After bending the pin out

the way then just be carfull not to floor it while still cold or your engine will stumble, bog and may even stall if its ice

cold.

|

|

|

|

|

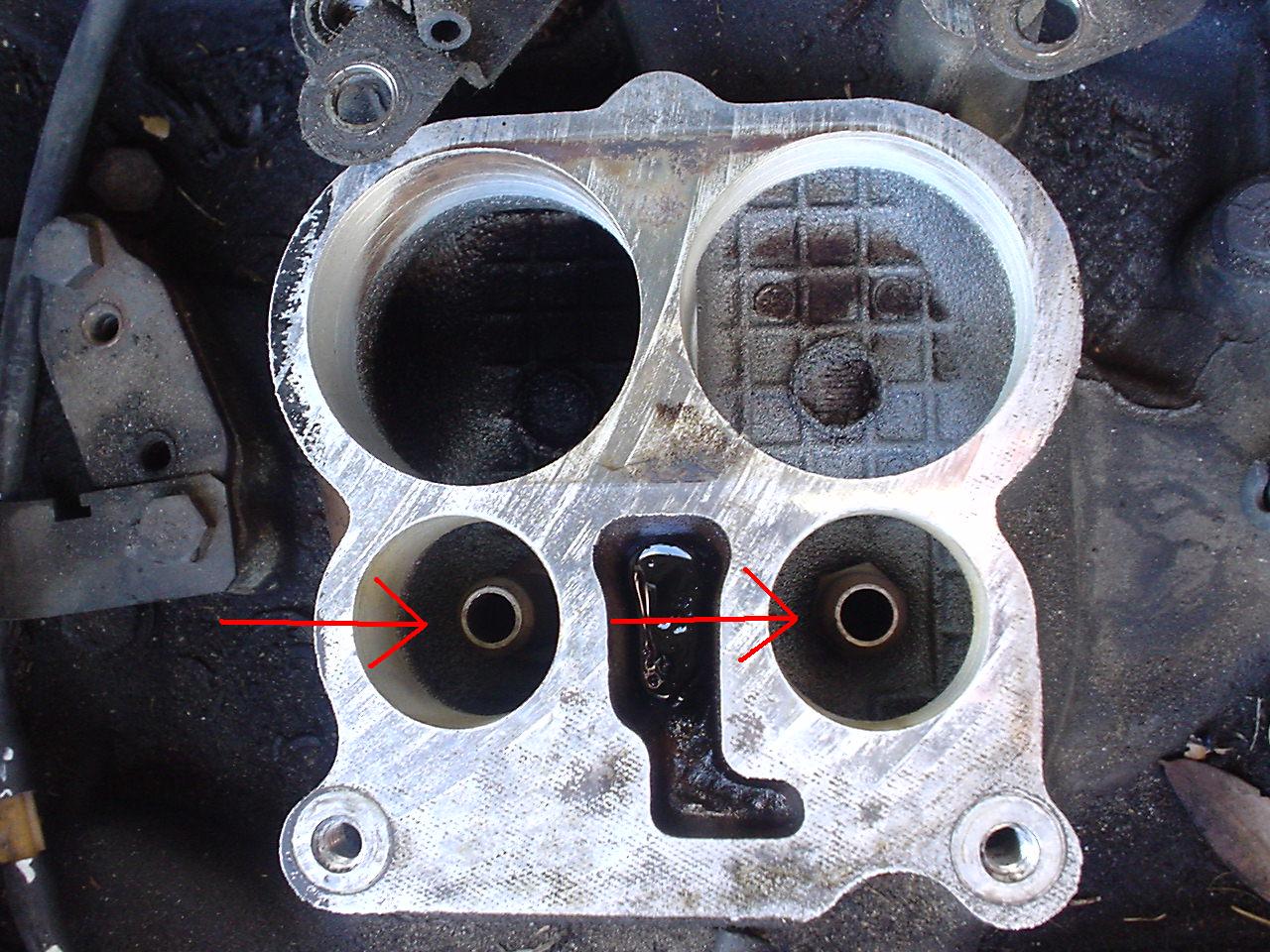

| The red arrows point at the EGR discharge tubes |

|

|

|

|

|

|